This would include the monitoring of material moved into and out of stockroom locations and the reconciling of the inventory balances. It also may include ABC analysis, lot tracking, cycle counting support, etc. All of these practices leads to optimal product storage, helping minimize holding and handling costs.

See advice specific to your business

That means that once your inventory hits 60, it’s time to place another order. To calculate reorder point, you’ll need to use the reorder point formula. If we total those numbers, we get 180 total units sold over the past 90 days. A reorder point is based on your purchase and sales cycles and varies by product.

How to use the reorder point formula to benefit your business

- The EOQ is the point at which the company’s ordering and carrying costs are equal.

- By doing so, you create a safety net that protects your business from the unforeseen without tying up unnecessary capital.

- Handling these calculations manually is doable, but as your inventory grows, it can become quite a task.

- Reorder point is the level of inventory that triggers a replenishment order.

- In other words, you should reorder stock when your inventory equals the total number of items you expect to sell during your supplier’s typical lead time plus your safety stock.

- Otherwise, the business might reorder parts when the intent of the inventory manager is to flush the part from stock.

Both ROP and EOQ play critical roles in effective inventory management, albeit utilized at different stages and for various facets of the inventory management process. It becomes especially crucial when handling products with diverse seasonal demands, shelf lives, or supplier conditions. Reorder points are integral within a broader supply chain framework, encompassing suppliers, manufacturers, and logistics partners. To keep your shelves nicely stocked, you gotta know how fast your products are flying off them—that’s your demand rate. Having enough safety stock means you’re ready for whatever comes your way.

Boundless: Business “Chapter 16, Section 4, Part 2: Inventory Management”

Customers will simply look elsewhere to buy the product—a process the Internet has made easier than ever. Many moons ago, when I was a broke college kid, my parents bought my first car from a junkyard (the first red flag). It worked insofar as it got me from Point A to Point B, but the “features” which one of these would not be a factor in determining the reorder point? of the car left a lot to be desired. I had no clue when the car needed to be filled up and just arbitrarily stopped at gas stations when I “felt” like it was time. This is how ecommerce businesses operate when they don’t use the reorder point formula to calculate reorder points.

- For example, maybe you saw a random spike in your sales numbers, or there was an extreme delay in delivery times due to unforeseen circumstances.

- Reorder point takes more into account than how much of a particular item your business needs.

- Having enough safety stock means you’re ready for whatever comes your way.

- Priced at about $2,500 the Tata Nano is the least expensive car ever produced in the world.

- Platforms like SkuVault Core will even calculate a recommended order amount based upon either your sales history or a manually set reorder point.

- This will effectively warn you when you need to start on a new purchase order.

- This method simply calculates the average amount of inventory that is used over a period of time and orders that quantity when inventory levels reach a certain point.

Reorder Point – Definition, Importance, Formula & Implementation

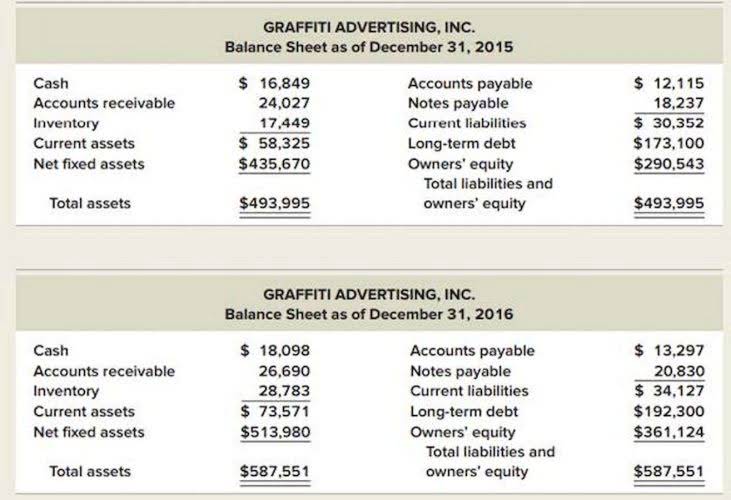

This may seem prudent on its face, but when you study your cash flow statement and see how much money ties up in stock, you realize how detrimental it is to your profitability. You may find yourself stuck with inventory you eventually have to dump (especially if you’re dealing with perishable items). Nature and Importance of InventoryInventories are necessary for a firm to operate efficiently and almost all business transactions involve the delivery of a product or service in exchange for currency. For this reason, inventory management is a very important part of core operations activities. Most retail businesses and wholesale organizations acquire most of their revenue through the sale of merchandise (inventory).

Once inventory dips below the calculated reorder point, replenishment is triggered through a new purchase order. The reorder point is a supply chain and inventory management technique businesses can use to guide this delicate balancing act. It improves inventory operations, avoids stockouts, and maintains ideal inventory levels. Inventory control is the process of ensuring your firm has an adequate supply of products and a wide enough assortment of them meet your customers’ needs. A stockout occurs when you run out of a product a customer wants to buy.

Better forecasting

Mastering the ROP is an essential skill in the art of inventory management. While understanding ROP offers numerous benefits for inventory management, implementing it is not without its challenges. Determining the right amount of safety stock is a critical component in the implementation of an effective ROP system, yet it can be a complex task. It represents the specific level at which your stock of a particular item is low enough that you need to order more. However, by demystifying ROP, we can transform it from an enigmatic concept into a powerful, practical tool for inventory management.

- If you’re a spreadsheet user, you can use conditional formatting for the quantity value of specific cells.

- Over those three months (or 92 days), an average of 1.5 units were sold daily.

- For example, when the economy hit the skids in 2008, the demand for many products fell.

- Safety stock is a term used in inventory management that refers to a level of extra stock that is maintained to mitigate the risk of stockouts.

- Keeping tabs on how much you have in stock and knowing when it’s time to restock keeps the business open.

- Having the right Inventory management system simplifies your responsibility.

Lead times also have to be taken into account when a company is forecasting demand. For starters, seasonality can drastically affect demand for your product. For example, you’re likely to sell more baseball bats right before your community’s youth baseball program starts. That means, during that time period, you’ll have a higher number of average daily sales and maximum daily sales. Maintaining reorder point ensures that there is perfect amount of inventory on hand to meet customer demand, while also avoiding the costly consequences of stock outs. By keeping a close eye on inventory levels and using the reorder point formula to guide reordering decisions, inventory managers can strike the perfect balance between too much and too little stock.

Improved forecasting

The important part is that these reasons are evaluated for the needs of each organization and an inventory management system is created that allows for the highest level of efficiency possible. Master your inventory holding costs with actionable tips and calculations. Reduce expenses, optimize storage, and streamline delivery with eLogii. Stockouts lead to longer wait times for customers, which nobody likes. Handling these calculations manually is doable, but as your inventory grows, it can become quite a task. You might want to think about using tools like Excel or dedicated inventory management software to help you keep track of your numbers more easily and efficiently.